Predyct Platform: IoT and Cloud

Smart sensors and advanced analytics for an actionable digital twin

Predyct IoT

Nano-Engineered Sensors

Predyct’s sensors utilize nano-engineered materials to continuously encode current asset condition via permanent physical changes without the need for power.

The sensor units have been extensively tested through rigorous defense, aerospace and industrial standards over the past several years. Benefits of these innovative sensors include ease of installation, ability to be massively scaled and having a high degree of durability and reliability.

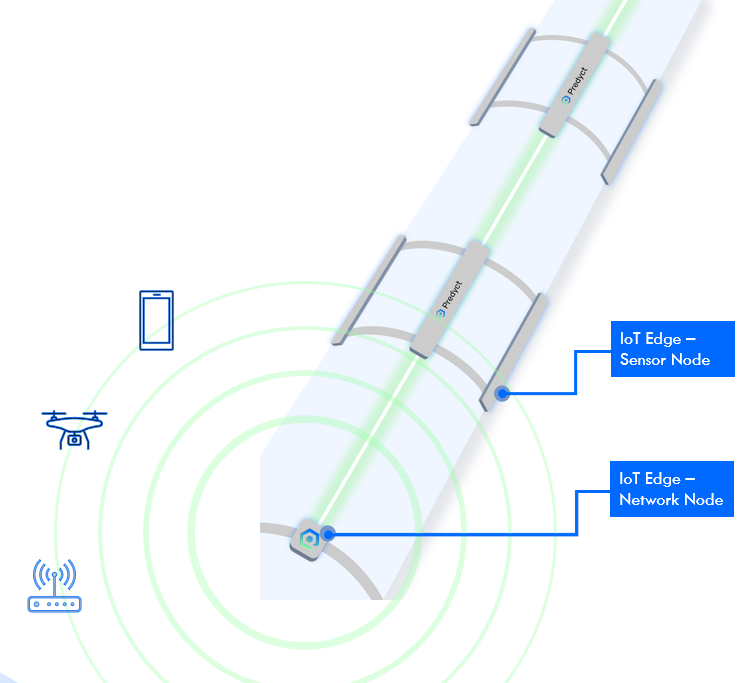

Sensor Network, Wireless Power and Data

For a large scale deployment, local area sensor networks provide ease of data access. Several ‘Sensor Nodes’ with multiple sensor types in close proximity are connected to a single ‘Network Node’.

Battery-free sensor networks harvest power wirelessly only when data acquisition is required. In proximity to a Gateway, the Network Nodes activate and transfers data wirelessly from each of the Sensor Nodes.

Predyct Cloud

Data Management and Analytics

The IoT Gateway sends secure data packets wirelessly while the cloud provides decryption, authentication, access control and smart-sensor processing. Raw sensor data is transmitted through the IoT Gateway, and calibration, validation and analysis are performed in the Predyct Cloud.

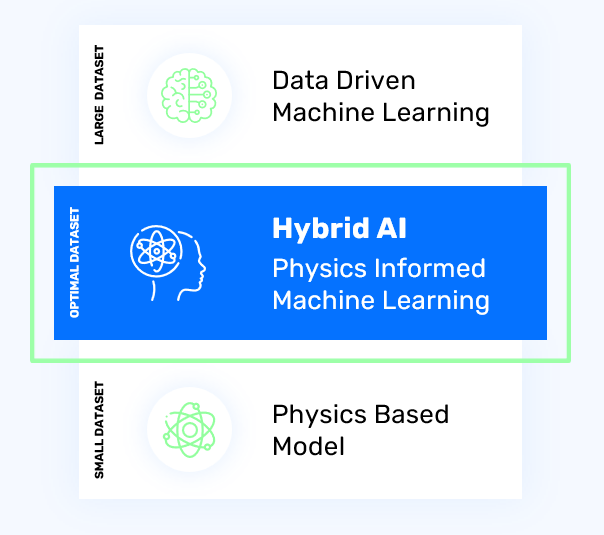

Predyct’s Cloud-based data analytics uses a combination of Physics and Machine Learning based models to translate data into asset intelligence. Predyct’s algorithms are continually learning and improving in accuracy to characterize complex system dynamics and processes.

Prediction and Insights

Predyct’s approach is to enable prognosis, not diagnosis. We empower operations to prevent expensive and sometime catastrophic failures through early detection of anomalies and timely remediation.

We collaborate with an ecosystem of customers and partners to convert measurements into actional insights. The insights are delivered through modular applications in the areas of proactive planning, integrity management, compliance, life extension and sustainability.

Features and Specs

Several product configurations to deliver best fit for the application

Sensor Types

Nano-Engineered: Crack, Fatigue, Corrosion, Erosion

General Purpose (partner): Strain, Humidity, Temperature, Pressure others per application.

Installation

Direct attachment to the host asset or

witness interface to capture condition leveraging industry standard methods

Sensor network power requirement

Battery-free sensor network has no on-board power

Battery-assisted sensor network configured for 10+ years life to support remote deployment.

Data acquisition frequency

Continuous tracking by Predyct sensors through permanent physical change.

Data transfer frequency/period is configurable per application requirement.

Serialization, Security and Interface

Global unique identification for each sensor, role-based access control, REST API for interface with the customer and partner ecosystem.